1. Application background

Inkjet, as an important part of the advertising media industry chain, has experienced a process from weak to strong in the past ten years, according to the data provided by the authoritative department: at present in China, the annual growth rate of outdoor advertising business is basically more than 30%, and inkjet production costs account for about 10% of the total cost of advertising, with huge prospects. The materials available for inkjet painting basically cover all media in addition to air and water, common linoleum, glass, porcelain, plastic and so on.

Lisan launched a special step control solution for the current situation of domestic advertising inkjet machine, which has been successfully applied and widely promoted in a domestic advertising equipment company. The solution adopts Lisan DMA545 stepper driver and LS57 series stepper motor, with the touch screen, PLC, frequency converter, frequency conversion motor and other components of the client to form a complete set of stepping solutions. The program has excellent performance and high cost performance.

2. electrical structure and process flow

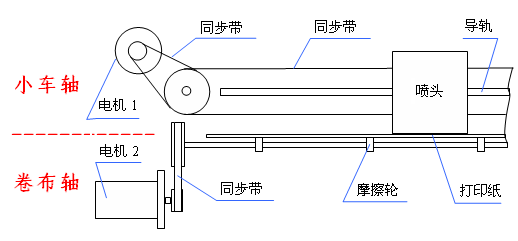

As shown below, the mechanical structure of the inkjet machine is belt drive, which is divided into small axle and roll axle:

1) The small axle ---- drives the nozzle movement, the load is heavy, the speed is fast, the start and stop is stable, and the torque ripple is small;

2) The winding shaft ---- drives the movement of the printing material, the load is light, the speed is not high, and the start and stop are required to be stable;

3、Stepping system

The machine adopts Lisan DMA545 intelligent digital stepping driver, which adopts the latest special motor control DSP chip and applied vector control technology, and has superior performance. The automatic parameter adjustment function is integrated inside the driver, which can automatically generate the optimal operating parameters for different motors. At the same time, the driver has overvoltage, undervoltage, overcurrent protection, its input and output control signals are photoelectric isolation, with high reliability.

◆ New 32-bit motor control DSP chip;

◆ Input voltage: 24-80VDC, output current: 1.0A~4.5A;

◆ Adopt resonance suppression technology, automatically calculate the resonance point, inhibit the medium/low frequency vibration;

◆ Can drive 4, 6, 8 wire two-phase 57/60 series stepper motor;

◆ Optocoupler isolated differential signal input, pulse/direction/enable signal (5V~24VDC compatible);

◆ Pulse response frequency up to 200KHZ; 16 subdivisions are available (200-25000 range);

◆ Precision current control greatly reduces the motor temperature rise;

◆ With over current, over voltage and tracking error and other protection;

◆ Error signal digital output: OUT+/OUT-;

4、Field debugging result

The basic parameters of the inkjet printer are as follows:

lEESN The configuration scheme is (small axle/reel axle) : DMA545 stepper driver + LS57A stepper motor

Field tests have proved that the inkjet speed, ripple and other aspects are comparable to servo motors, with strong competitiveness.

5、peroration

The application of Lisan DM series stepper system in inkjet machine is of great significance for domestic electromechanical automation system technology to form a breakthrough in this industry. The project plays a very positive role in the high-end application of domestic brand stepper/servo system in the field of advertising inkjet machine.