1、Industry overview

For tobacco commercial enterprises, a reasonable cigarette sorting system means smooth coordination of the material flow line, stable and reliable sorting efficiency, accurate and efficient sorting quality, and fully respond to the requirements of "national interests first and consumer interests first" advocated by the State Tobacco Monopoly Administration.

Since 2000, cigarette sorting system has been put into use in various tobacco companies. After ten years of development, through continuous innovation and progress, cigarette sorting has been greatly improved and improved from electronic label picking mode to vertical and channeling semi-automatic sorting, and even automatic replenishment, sorting, packing, wrapping film, sorting process and equipment performance. It provides a more powerful support platform for tobacco companies to better serve consumers, and also provides a strong guarantee for improving the logistics level of China's tobacco industry.

2、Tobacco sorting system introduction

The sorting system of cigarette distribution center of tobacco company mainly includes three main parts: pallet storage, pre-sorting cache and strip sorting.

The following takes a northeast tobacco company as an example to introduce the process of tobacco sorting

2.1、Cigarette pallet storage

Tobacco distribution center storage is mainly divided into shelf storage and warehouse storage two categories, according to different annual sales in different places to choose different forms.

2.2、Stock cache

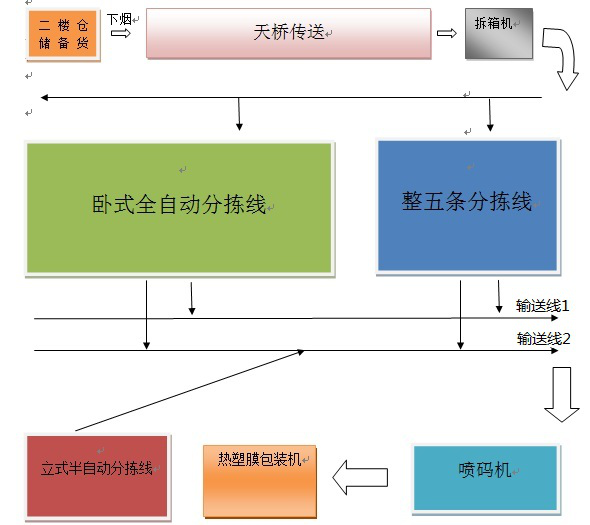

In the distribution center, the second floor is the storage location, and the smoke is manually carried on the conveyor belt, which is sent by the vertical transmission mechanism to the overpass transmission belt on the first floor.

2.3、devanning

The lift will send the smoke from the bridge to the automatic unpacking machine. After the unpacking, the cylinder will push the smoke to the pallet on the conveyor belt, and the carton will be automatically flattened and stacked.

2.4、sort

Tobacco sorting equipment is divided into three types: the whole five sorting machine, vertical sorting machine, horizontal sorting machine. The whole five sorters are suitable for the same variety and number of sorting, the horizontal sorter is suitable for multi-variety and small batch sorting, the vertical sorter and the horizontal sorter are similar, the difference is that the vertical sorter needs manual smoke.

Each channel of the sorting equipment has a sensor, and according to the type of cigarette and the order demand, the cylinder transmission mechanism of the channel will push the cigarette into the sorting equipment.

The exit of the sorting equipment uses servo control, and the strips of smoke are sent to the conveyor belt one by one according to the order quantity.

2.5、Laser coding

2.6、Heat shrink film packaging

The complete tobacco sorting line composition is shown below:

3、Servo control scheme

In this distribution center, two stations are switched up and down the sorting equipment channel outlet and the conveyor line respectively using servo motor control.

3.1、Sorting line each channel exit location

The servo motor drives the chain through the synchronous belt wheel, the two-wheel ratio is about 1:2.5, using the internal speed control, the sensor receives the smoke arrival signal, and the servo starts according to the need, and the smoke is sent out through the stop on the chain.

3.2、Transfer line lower switch

Taking into account the sorting efficiency, the sorting equipment channel outlet is a high-low cross design, can be sent to the upper and lower two layers of conveyor lines, to the laser coding machine position, the two layers of conveyor lines converge to a layer, after the end of the coding and then transported to the upper and lower two layers. As shown in the picture:

The servo motor drives the left platform up and down through a connecting rod, and the smoke is sent to the upper and lower two layers of the right conveyor line according to the requirements. The drive adopts internal speed control, and two photoelectric switches are installed at the crankshaft corresponding to the upper and lower positions respectively. When the servo stops, the servo response is required to be fast, the positioning is accurate, and the noise is low.

4、Sum up

Tobacco sorting equipment for the servo motor requirements are not complex, but the number of on-site servo motors, 24 hours of operation, three servo motors with excellent stability and high responsiveness, long-term stable operation in the distribution center, greatly improving the efficiency of tobacco sorting.