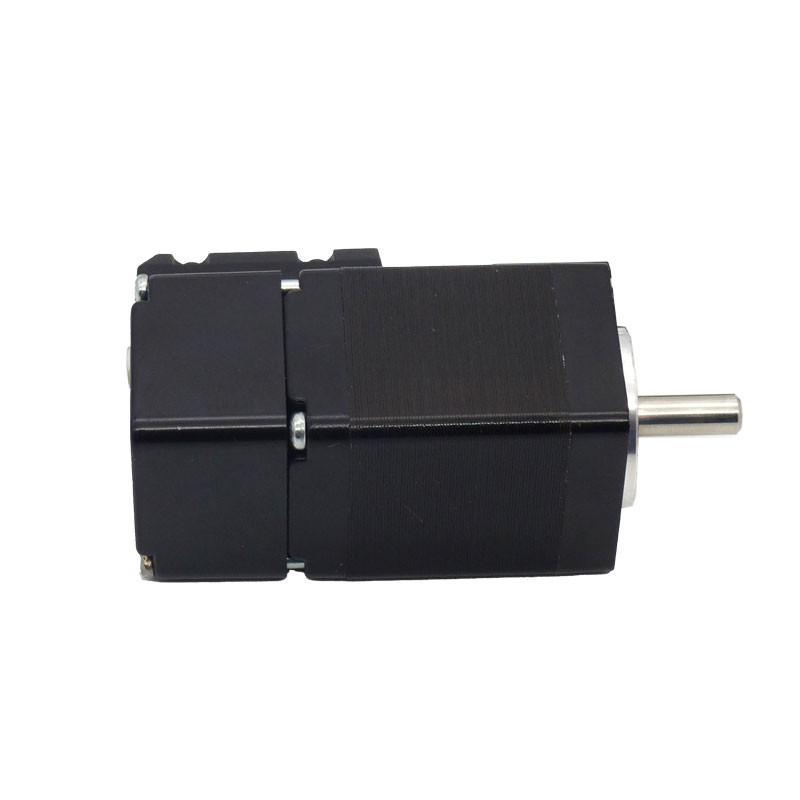

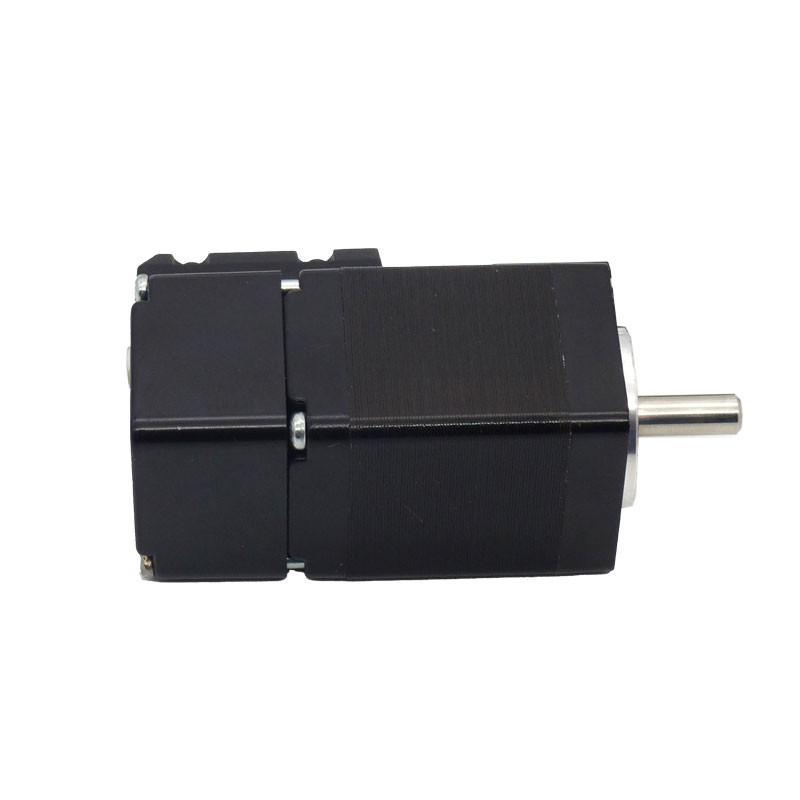

LS28E008-B2B10 Closed-loop stepper motors

LEESN new generation 28mm*28mm(NEMA11) two-phase 1.8° closed-loop stepper motor, built-in 2000 wire encoder, with miniaturized design, low heating, high stability, high consistency, greater torque, higher performance, recommended for the driver DE42.

① Spindle mode:

Provide single flat, double flat, keyway, hobbing and other shaft delivery modes;

② Lead mode:

According to different application requirements, provide customized winding and routing methods;

③ Accessories selection:

Provide a variety of accessories for the stepper motor, such as planetary reducer, power off brake, etc.

The working principle of closed-loop stepper motor is based on feedback control. Encoders or other position sensors constantly monitor the position of the motor and feed the actual position information back to the motor controller. The controller compares the target position and if an error is detected, it adjusts the motor's control signal accordingly to correct the error and move the motor to the correct position.